ASSET PERFORMANCE MANAGEMENT

APM LEAD

LEADERSHIP, ENGINEERING, ADVANTAGE

Conference & Exhibition

July, 2025

APM LEAD is a conference and exhibition that gathers professionals from various asset-intensive industries to discuss innovations and strategies in Asset Performance Management (APM). The event focuses on enhancing the efficiency and reliability of industrial assets through technology, data-driven solutions, and collaboration. Attendees explore topics such as improving operational performance, reducing downtime, predictive maintenance, and leveraging emerging technologies like AI and IoT. The goal of APM LEAD is to foster knowledge-sharing and partnerships that help industries optimize their assets while addressing broader challenges like sustainability and resource management

Delegate

- Enhance your plants reliability

- Foster Valuable Connection

- Stay updated on cutting edge technologies

- Increase your value to the company

- Implement solutions

- Save on expenses

- Expand business opportunities

- Attend a day of workshops

- Share insights with colleagues

- Invest in growth

Speaker

- Gain recognition from your industry peers

- Contribute to the advancement and education of attendees

- Showcase your work, lessons learned, success stories, results, and expertise

- Earn course hours toward your industry continuing professional development certifications

- Complimentary registration to the event for the primary presenter

- Have your paper published in the Asset IQ Magazine

Sponsor

- Speaking opportunity

- Exhibit your products and services

- Place your brand all throughout the conference event materials

- Network and collaborate with the guests on a one-on-one meeting session

- Have your marketing materials published on all conference websites and social media pages

- Get access to the post event report with the guest contact details

CO-LOCATED EVENT

KEYNOTE SPEAKER:

Director IV, Governance Staff - Office of the Director

National Economic and Development Authority

2024 THEME

SUSTAINABLE FUTURES: ENGINEERING AND ASSET MANAGEMENT FOR GLOBAL GOALS

2024 ADVISORY COUNCIL

CSAM, MBA, MScENG, BScENG

Chief Asset Management Officer

Aboitiz Power Corporation

Mr. Voltaire Jerome Cruz

MBA

General Manager-Field Execution Optimization

Shell Shared Services Asia B.V.

Mr. Toribio Noel Ilao

CSAM, CAMA

Director IV - Bureau of Equipment

Department of Public Works and Highways

(DPWH)

Mr. Marco Antonio "Dingdong" Altarejos

RME

Head of Operations

Prime Energy Resource Development B.V.

Sustainable Futures 2024 Highlights

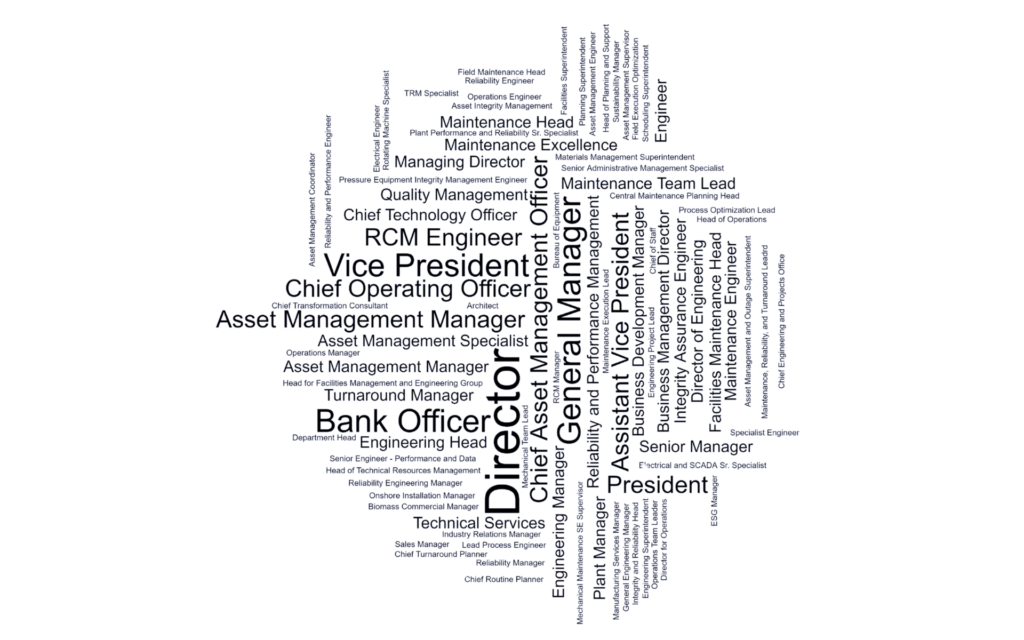

Job Title Attendees

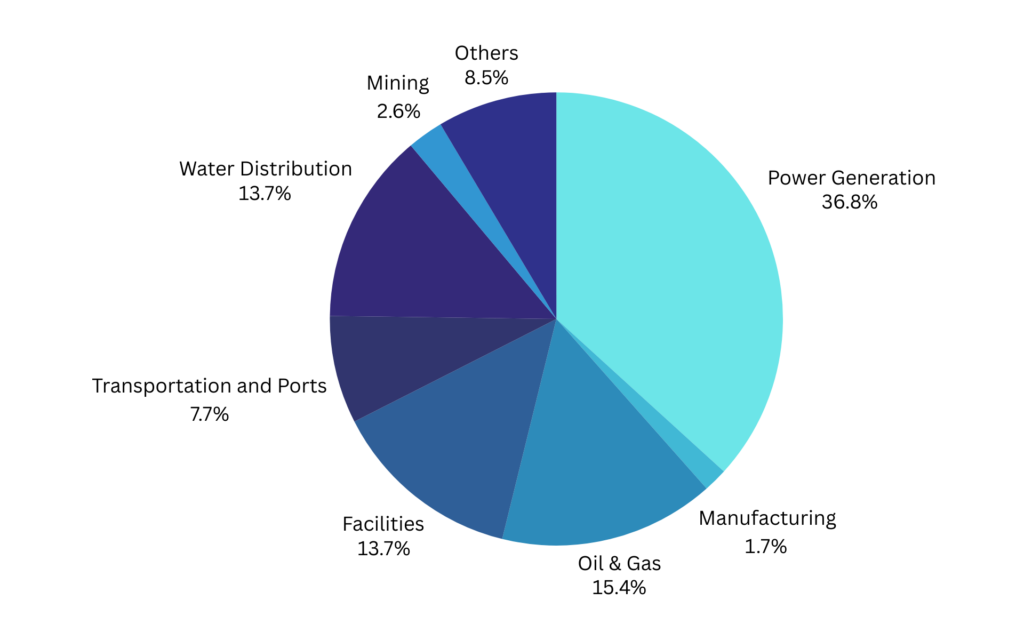

Industry Attendees

Company Attendees

The APM LEADCon 2024: Sustainable Futures, held from July 3-5, 2024, at Citadines BayCity Manila, gathered industry leaders and professionals in asset management and reliability to discuss pressing topics centered around sustainability and innovation. Through a series of insightful plenary sessions, participants explored strategies for aligning...

Manila, Philippines – July 3-5, 2024 – The APM LEAD Conference and Exhibition 2024, themed "Sustainable Futures," concluded successfully after three days of insightful discussions, innovative exhibitions, and impactful networking. Held from July 3-5 at the Citadines Bay City Manila, the event brought together thought leaders, industry...

From July 3rd to 5th, 2024, APM LEADCon 2024 brought together industry leaders under the theme “Sustainable Futures.” The conference focused on accelerating progress towards the United Nations Sustainable Development Goals (SDGs) by exploring how Asset Performance Management Leadership, Engineering, Advantage (APM LEAD) can address global...